3D Printing Revolution: Transforming Ideas into Reality

Advancements in technology continually shape the way we approach various industries, and 3D printing stands as a testament to innovation’s transformative power. This revolutionary technology has transcended traditional manufacturing methods, opening up new possibilities across diverse fields.

The Basics of 3D Printing Technology

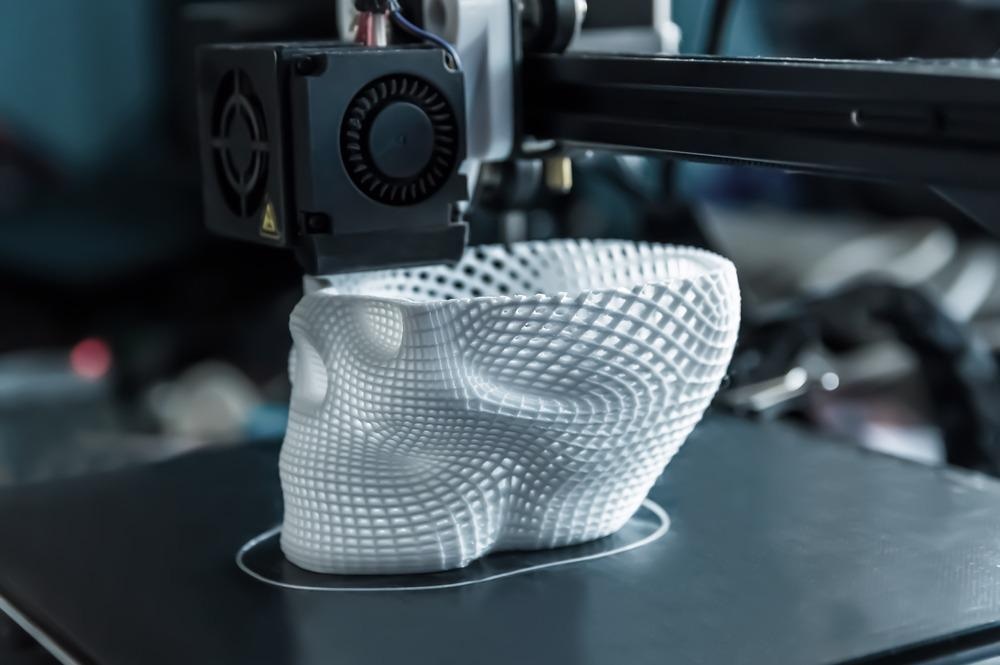

At its core, 3D printing, also known as additive manufacturing, involves creating three-dimensional objects layer by layer from digital models. This departure from subtractive manufacturing processes enables the fabrication of intricate and complex structures with precision and efficiency.

Applications Across Industries

3D printing’s versatility is evident in its applications across a multitude of industries. From healthcare and aerospace to automotive and consumer goods, this technology has proven instrumental in prototyping, custom manufacturing, and even the production of end-use parts. The ability to create bespoke items quickly and cost-effectively is reshaping manufacturing landscapes.

Prototyping and Rapid Iteration

One of the primary advantages of 3D printing is its role in prototyping. Designers and engineers can swiftly transform digital concepts into physical prototypes, allowing for rapid iteration and refinement. This expedites the product development cycle, enabling faster bring-to-market times and cost savings.

Customization and Personalization

The capability to create highly customized and personalized products is a hallmark of 3D printing. Whether it’s tailored medical implants, bespoke consumer goods, or unique architectural elements, 3D printing empowers the production of items tailored to individual specifications.

3D Printing in Medicine

In the healthcare sector, 3D printing has achieved remarkable milestones. From creating patient-specific surgical guides to crafting intricate models of organs for pre-surgical planning, this technology has revolutionized medical practices. The potential for 3D-printed organs and tissues is an ongoing area of exploration.

Sustainability and Reduced Waste

The sustainable aspect of 3D printing is noteworthy. Traditional manufacturing processes often generate significant waste, whereas 3D printing is additive, utilizing only the necessary materials. This reduction in material waste aligns with global efforts toward more sustainable and eco-friendly practices.

Challenges and Technological Advancements

Despite its transformative potential, 3D printing faces challenges such as material limitations, speed constraints, and post-processing requirements. Ongoing research and technological advancements are addressing these challenges, paving the way for improved capabilities and broader adoption.

3D Printing in Education and DIY Projects

Education has also embraced 3D printing, providing students with hands-on experiences in design and manufacturing. Additionally, the accessibility of desktop 3D printers has fueled a thriving community of DIY enthusiasts and makers, fostering creativity and innovation at the grassroots level.

Future Prospects: Industry 4.0 and Beyond

As we delve into the era of Industry 4.0, 3D printing is positioned as a cornerstone technology. The integration of 3D printing with data analytics, artificial intelligence, and the Internet of Things (IoT) heralds a future where manufacturing processes are not only automated but also highly intelligent and responsive.

Explore the 3D Printing Revolution at NyNeighbor.com

For an in-depth exploration of the 3D printing revolution and its impact on various industries, visit NyNeighbor.com. Stay informed about the latest trends, innovations, and opportunities within the realm of 3D printing.

In conclusion, the 3D printing revolution is not merely a technological advancement; it’s a paradigm shift in how we conceive, design, and manufacture objects. With its widespread applications, customization capabilities, and ongoing advancements, 3D printing is poised to play a pivotal role in shaping the future of manufacturing and design.